Few things impact an industrial facility’s utility bill more than peak loads. These are periods of high energy usage, usually in the evening or during weather extremes when the grid is strained and renewables aren’t available. To meet this demand and avoid blackouts or brownouts, utilities are often forced to rely on fossil fuel peaker plants, causing electricity rates to soar.

For industrial facilities, this becomes especially problematic when the bulk of their energy usage is during peak load periods, resulting in costly demand charges. But how can industrial facilities avoid these costs while still powering their mission-critical operations?

There are two options: peak shaving and load shifting. While both energy management approaches reduce stress on the grid, they differ in their timing, approach, and objectives.

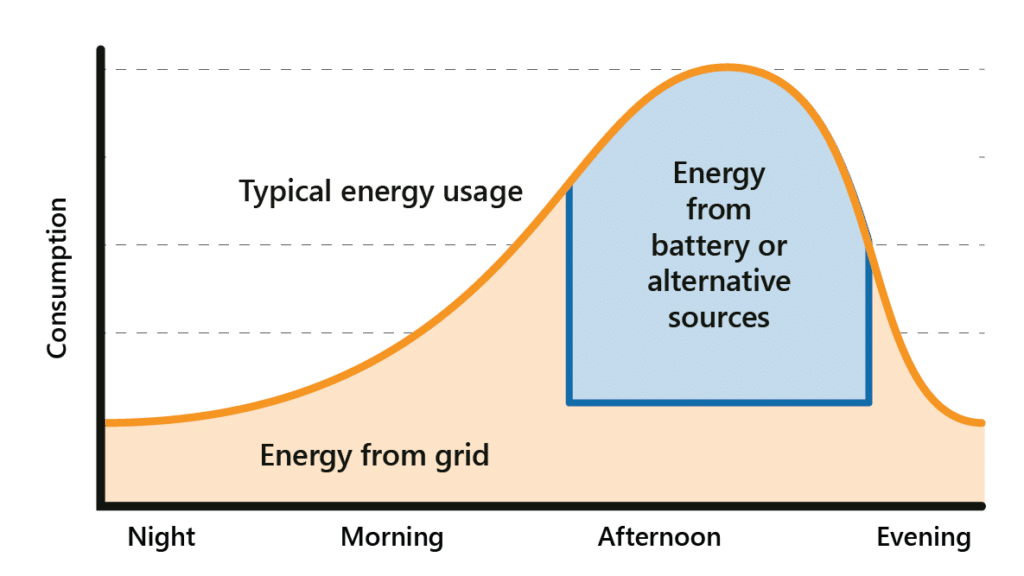

Peak Shaving Explained

Peak shaving is about reducing energy consumption during peak demand. As its name suggests, it involves ‘shaving’ energy peaks. At peak demand, another energy source besides the grid will be used. Often, this is a demand-side battery that stores energy during off-peak times when renewables are abundant to be discharged at peak times.

Batteries add reliance and stability to the grid. They’re also an essential resource for reducing an industrial facility’s energy bills as they avoid reliance on the grid at peak times when energy is the most expensive. Demand-side battery energy storage systems can also be bidirectional, meaning they can discharge to the grid, helping further balance the grid while adding an additional revenue stream to industrial facilities.

Bidirectional Charging In ActionIn 2019, we activated a 1 MW/ 4 MWh demand-side battery system on the premises of a manufacturing site in Kearny Mesa, San Diego. The battery is used for time-of-use rate shifting, demand charge reduction, and demand response. In addition to the site being equipped with a CAISO and RIG, the energy system can be managed and optimized with Peak Power’s software, Peak Synergy, turning it into a flexible grid resource. This project has delivered approximately $554,000 in savings since it came online in 2019. |

Peak shaving can be achieved with different technologies:

- Battery energy storage systems: Solve for the intermittency of renewables, storing energy when renewables are abundant to be discharged at peak times

- On-site generation: This includes solar and wind turbines, which produce energy that can be used during peak demand. Works best when combined with energy storage

- Curtailment: Where a facility intentionally limits or reduces its power consumption by powering down non-essential machinery and operations.

- Energy efficiency: Energy efficiency can help a facility reduce energy usage at peak times. In Toronto, for example, various energy efficiency measures, like adjusting a facility’s global temperature and optimizing chiller temperature setpoints, can save on Global Adjustment fees.

| Example of Peak Shaving in Action | |

| Location | Ontario, Toronto |

| Activation | July 2022 |

| Capacity | 500 kW / 1,000 kWh |

| Overview | John’s facility has high energy demand during peak hours, especially in the summer. To reduce demand charges associated with this energy usage, the facility invested in a 500 kW / 1,000 kWh BESS. |

| Total Monthly Savings | Non-coincident charges (without BESS): $39,062.52 Non-coincident peak savings: $4,890.76 Using peak shaving, there was a savings of just over 12% on a single bill. These are based on a facility’s load and usage. A battery is used to shave off these charges. |

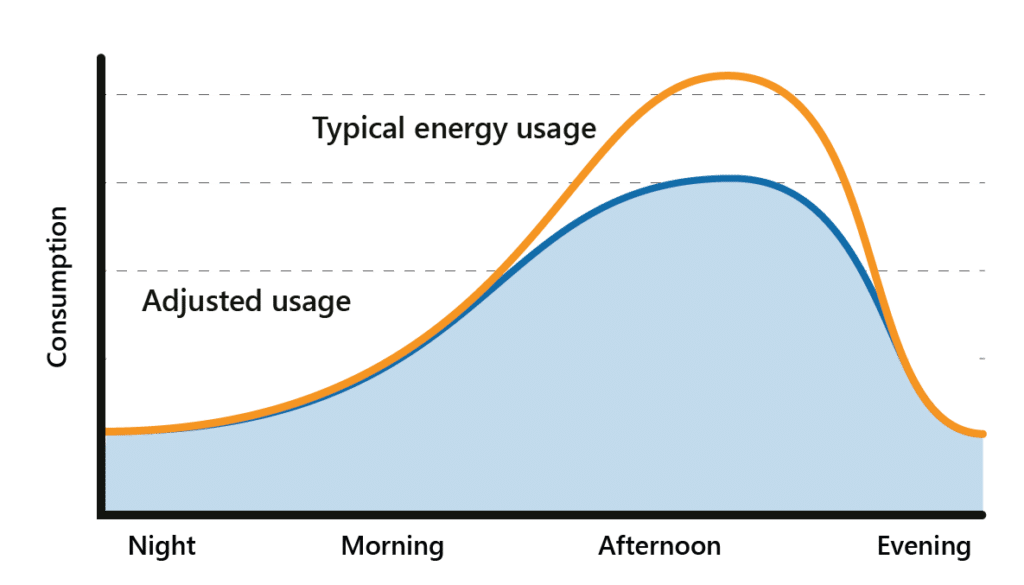

Load Shifting Explained

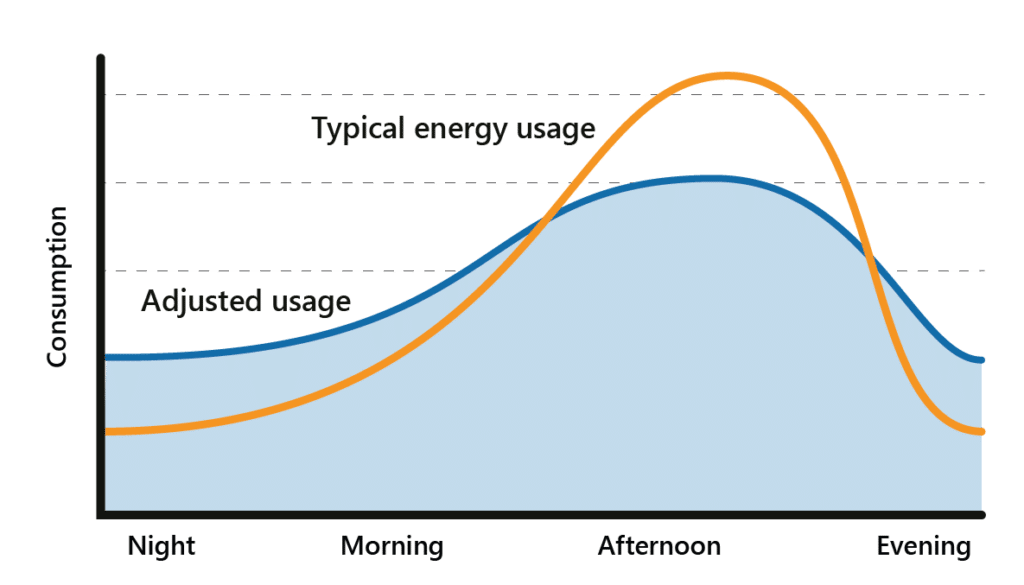

Load shifting is similar to peak shaving in that it aims to alleviate stress on the grid during peak times. But it works differently. With load shifting, energy consumption is shifted from peak hours to off-peak hours when demand is the lowest. This balances the grid by shifting demand to off-peak times. Load shifting is all about redistributing energy consumption.

A good example is an industrial facility that could schedule its machines to operate during the middle of the day when there’s less demand on the grid. Of course, this would only work if the machines aren’t mission-critical and can be operated at another time. And that’s one of the biggest drawbacks of load shifting.

Load shifting is all about when you use energy. In other words, when you use energy is just as important as how much you use it. That means that load shifting doesn’t actually reduce energy usage. It simply changes when you use energy.

There are several technologies for load shifting:

- Battery energy storage systems: In industrial facilities, energy storage systems can store energy at low cost during off-peak hours and discharge at high-cost peak hours.

- Load shifting without energy storage: A facility’s operation schedules for everything from thermostats to HVAC and equipment can be adjusted to suit different load-shifting models, moving energy-intensive activities to off-peak hours.

| Example of Load Shifting in Action | |

| Location | Ontario, Toronto |

| Activation | July 2022 |

| Capacity | 500 kW / 1,000 kWh |

| Overview | John’s facility has high energy demand during peak hours, especially in the summer. To reduce demand charges associated with this energy usage, the facility invested in a 500 kW / 1,000 kWh BESS. |

| Total Monthly Savings | Coincident peak charges (without BESS): $87,028.26 Coincident peak savings: $7,889.66 Using load shifting, there was a savings of just over 9% on this bill. The facility’s energy consumption is shifted in response to demand on the grid. |

Peak Shaving Vs. Load Shifting: Which is Right For You?

While both peak shaving and load shifting enhance demand-side flexibility, peak shaving manages peak loads while load shifting optimizes energy usage based on price or grid conditions. Another important difference is that peak shaving reduces the overall energy being consumed from the grid, while load shifting doesn’t reduce overall grid consumption. What does this mean for your facility?

For many industrial facilities, peak shaving is the best option as this reduces their heavy demand charges and energy usage without affecting the facility’s operations. This is key. Generally, facilities have inflexible loads that can’t be shifted to low peak hours. For example, there might be an HVAC system that’s crucial to the facility’s operations or a machine that needs to run continuously. In this case, it’s impossible to load shift.

The combination of renewables, such as solar power and demand-side energy storage, further enhances the appeal of peak shaving for industrial facilities. In this case, batteries store the renewable energy generated during the day, which can be utilized during peak times when the grid is under strain. Apart from the financial benefits and energy security, peak shaving also contributes to a facility’s sustainability efforts by reducing its carbon footprint and Scope 2 emissions. This comprehensive approach not only slashes energy bills but also is an essential part of the transition to a cleaner tomorrow.

Final Thoughts

Peak shaving and load shifting are a departure from how C&I buildings and industrial facilities have traditionally consumed energy. While different, both play important roles in the energy mix.

Navigating the world of energy management can be overwhelming, but it doesn’t have to be. We’re here to help you build a peak shaving strategy that suits your facility. Book a call with us to learn more about our solar and no-cost energy storage solutions.